Automated CNC 6 Sided Drilling Machine D5A

Core Highlights:

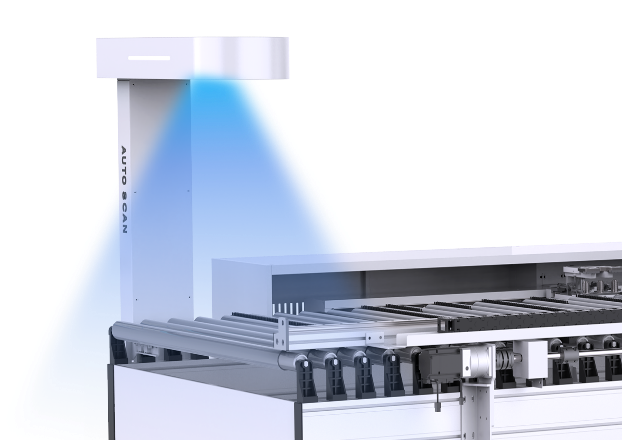

- Intelligent scanning with automatic return for scan errors.

- Unified visual line control interface with real-time processing status monitoring.

- Quick-connect plugs between the production line and main unit for easy connection.

- Minimum workpiece size: 200mm × 50mm.

- Flexible lifting mechanism for workpiece alignment, ensuring stable conveying.

- Precise positioning of workpieces.

- Intelligent double drilling heads and multi-post tool magazine meet various process requirements.

- When a size detection error occurs, the system automatically allows the panel to pass through and the outfeed end triggers an intelligent warning for the abnormal panel.

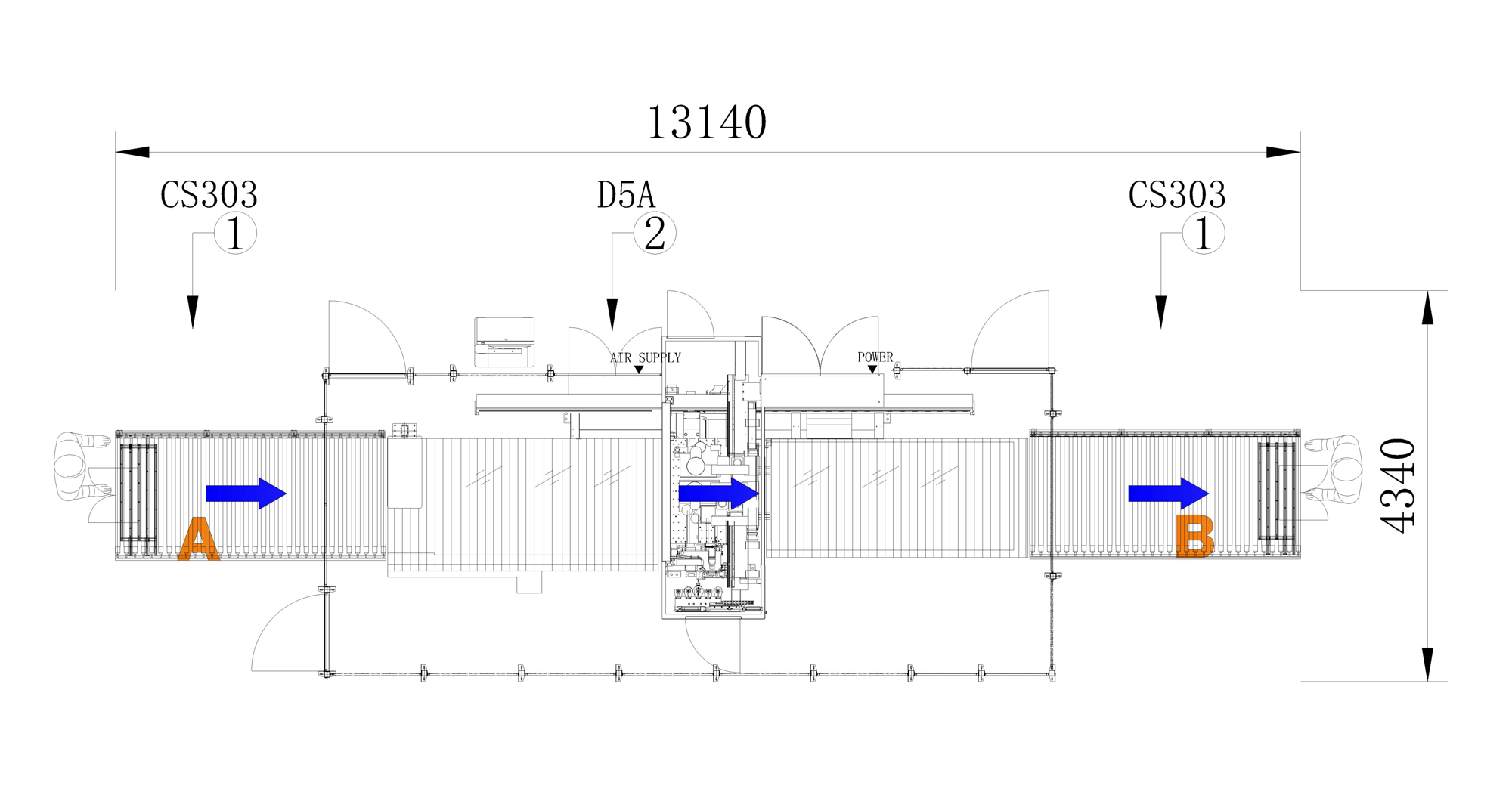

Automated CNC 6 Sided Drilling D5A Solution Layout

Technical Parameters – Full Line Operation

|

Panel length |

200-2800mm |

|

Panel width |

50-1220mm (≤200mm only Length side infeed) |

|

Panel thickness |

10-60mm |

|

Panel unevenness |

≤0.3mm |

|

Working pressure |

0.6MPa |

|

Working height |

950mm |

|

Speed |

70m/min |

|

Fence height |

1,800mm |

|

Size (L*W) |

13,140mm*4,340mm |

1. CNC 6 Sided Drilling Machine(D5A)

1. CNC 6 Sided Drilling Machine(D5A)

Functions:

Double-drilling heads CNC six sided drilling center has twin drilling heads for simultaneous processing with higher efficiency. Easy operation, lower workload, can be connected with variety of software. It is mainly used for six sided processing (hinge holes, through holes, semi-through holes) of various kind of artificial panels, horizontal drilling, and can simultaneously process symmetrical hole positions, also can work with grooving and milling with small spindles.

1.1Core Highlights:

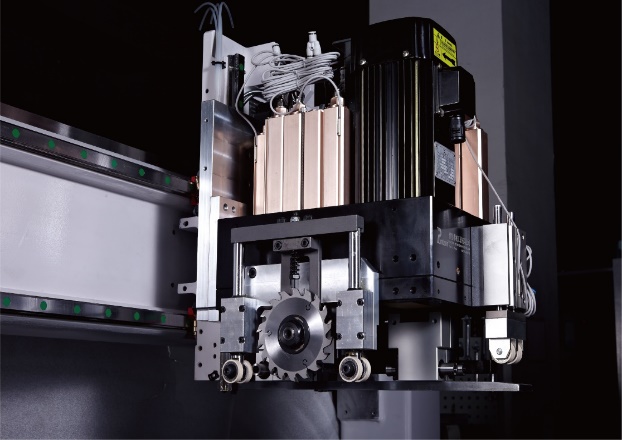

- The spindle with auto tool change, can handle various processing techniques such as grooving, milling and invisible parts.

- With double gripper and long guide rail,gripper max speed up to 140m/min,auto detect hole position to avoid gripper exchange time. Gripper trip up to 5.5 meter, catch big board by one time, reduce processing time.

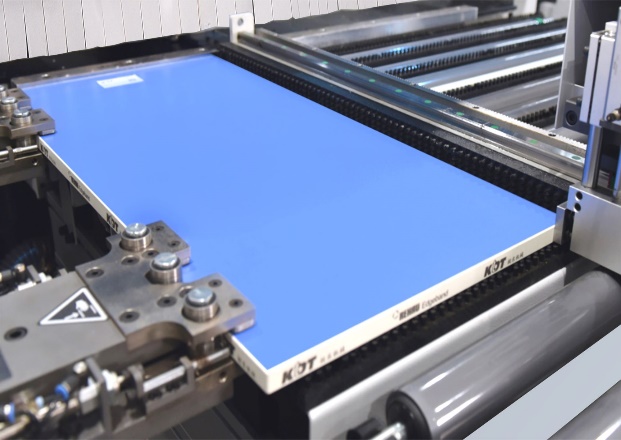

- Adopt double transitional air flotation table, move flexibly according to the hole position to improve the drilling accuracy and avoid dust at the bottom.

- Computer operation, CAD drawing, CAM import, can be directly imported DXF, MPR, XML and other open data formats, easy to operate.

- The system identifies the processing information by scanning code, which is intelligent and efficient.

- Front-in & back-out mode, the next panel can be processed instantly after the processing former panel, the whole process is smooth, short time standby, the front-in & back-out mode can be connected to production lines, and the comprehensive drilling has reached the level of the double-station PTP drilling processing center.

1.2 Technical Features(D5A)

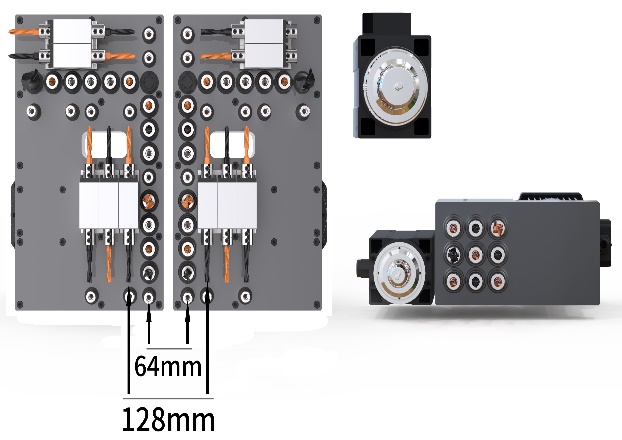

Drilling heads with tools

- Top drilling 2 blocks: 26(V)+18(H)

- Bottom drilling 1 block: 9(V)

- Max drill diameter: 35mm

- Speed 4,500 rpm (automatically change to 2,700 rpm when drill diameter is 35mm with FC)

- Shank diameter: 10mm

- Tool length: 70mm

- Max processing depth: 45mm

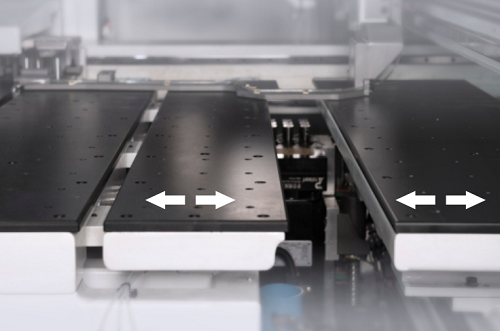

Double transitional air flotation worktable

It can move flexibly according to the hole position, reasonably support the panel, improve the drilling accuracy, and avoid dust accumulation at the bottom.

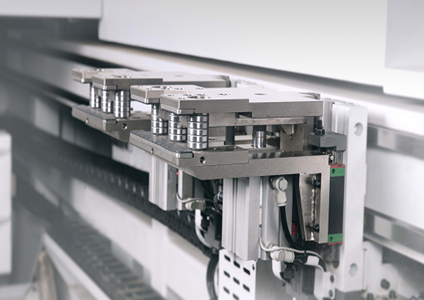

Upgrade dual gripper and long guide rail

Quick working with various panel holes.

Quick positioning and clamp

Parts automatic side pushing.

Belt conveyor dust collection

Remove dust which fall into machine.

Simulate processing path

Realize the visualization of the processing path and accurately predict the processing time.

Processing record statistics

View production progress in real time.

Intelligent barcode scanner

Barcode reading with 1 scanner (up to 600mm range) to identify the workpiece production requirement.

5 positions automatic tool change magazine

Automatic tool changer, various tool available for grooving, milling, lamello and other connector processing

1.3 Options (D5A)

Grooving function

- Optional grooving saw blade, it can work along the X direction within the width range of 55-880mm.

- Grooving saw diameter 120mm x width 6mm with max depth 20mm.

Two-side aggregate

- Can be equipped with various forming tools such as grooving saw, lamello tool, and Lecco milling cutters, enabling the processing of the side surfaces of panels.

- The max length of tools is less 50mm.

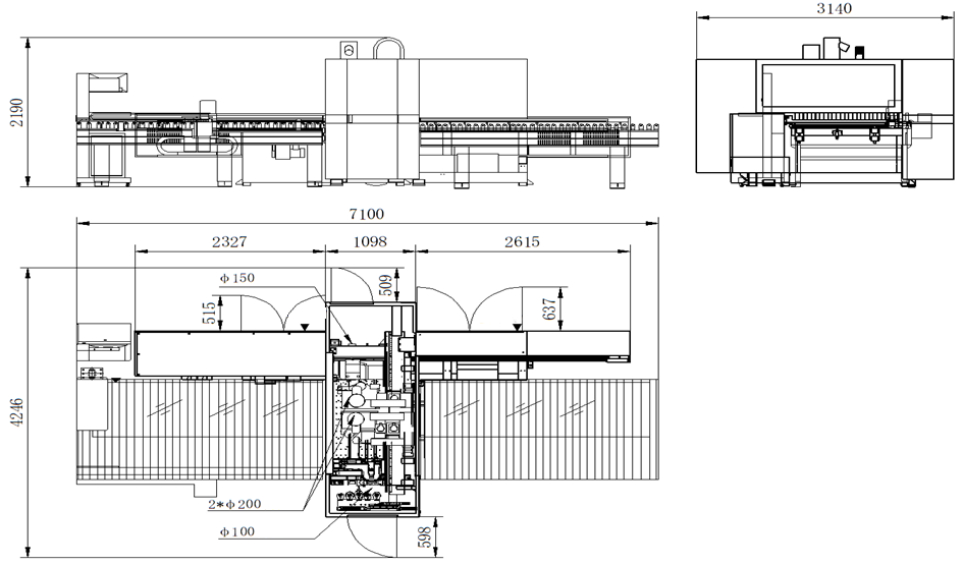

1.4 Layout(D5A)

1.5 Technical Parameter (D5A)

|

Packing size |

7400L*2300W*2445H mm |

|

Gross weight |

4300kg |

|

X/A axis max speed |

140m/min |

|

Y axis max speed |

90m/min |

|

Z axis max speed |

50m/min |

|

B axis max speed |

75m/min |

|

C axis max speed |

30m/min |

|

Tool quantity |

Top x 2 : 26(V)+18(H) Bottom x 1: 9(V) |

|

Spindle Index |

Top spindle: Power: 5.5kW / 12000-18000rpm adjustable (can link with different tools) with ISO30 interface Bottom spindle: Power: 3.5kW / 18000rpm |

|

Panel length |

200~2800mm |

|

Panel width |

50~1220mm (≤200mm only Length side infeed) |

|

Panel thickness |

9~60mm |

|

Panel unevenness |

≤0.3mm |

|

Power |

30.12kW |

|

Overall size |

7100L*3140W*2190H mm |

|

Air pressure |

0.6Mpa |

|

Vacuum tube size |

φ200mm*2; φ150mm*1; φ100mm*1 |

|

Air consumption |

450L/min |

|

Air volume in dust collection |

9540 m³/h |

|

Air speed at the dust inlet |

30m/s |

|

Tool magazine |

5 positions tools change magazine |

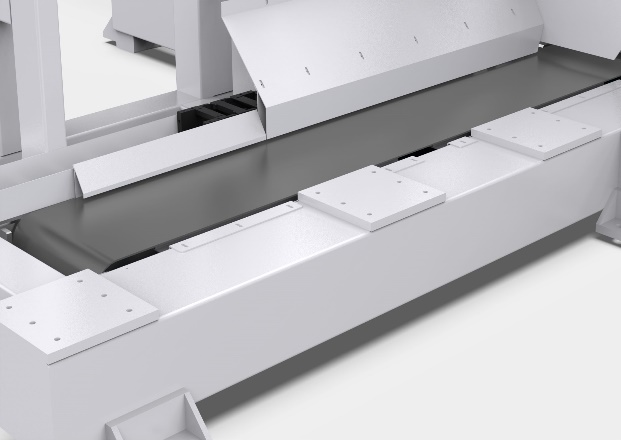

2. Roller Conveyor(CS303)

2. Roller Conveyor(CS303)

2.1 Layout

2.2 Equipment Functions

It is used for CNC 6 sided drilling line feeding and unloading, and automatic production line, with a wide range of application scenarios.

2.3 Core Configuration

- The integrated frame is equipped with 240*50mm high-strength aluminum, which runs smoothly for the whole line.

- Suitable for transition different sizes of panels, length 200-2800mm and width 200-1200mm, thickness 10mm-60mm. The min. panel size is 200*200mm and the max. width to length ratio is 1:7 (depending on customer's panel).

- The roller drive adopts variable frequency control, working speed max 26m/min with working air pressure 0.6Mpa.

- Independent PLC control, convenient for the layout of the production line and the modular docking between the machines.

- Independent control of electrical box and operation panel, convenient for manual operation and maintenance, total power 0.75kw.