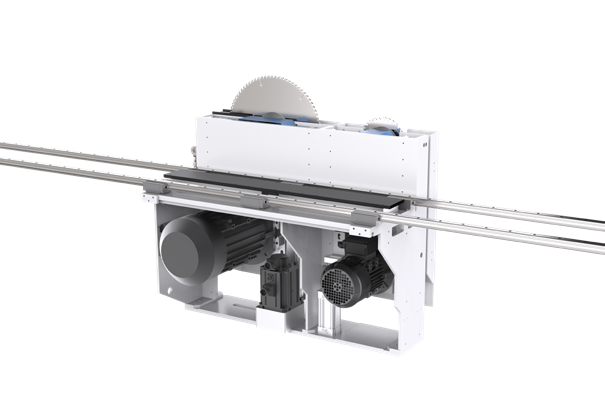

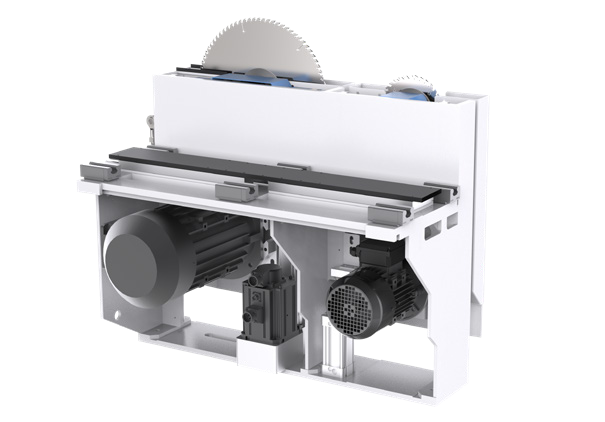

Saw carriage driven bylinear servomotor with speed 200m/min.

Main saw driven by a permanentmagnet motor, saw blade vertical movement with servo control, can realize grooving function.

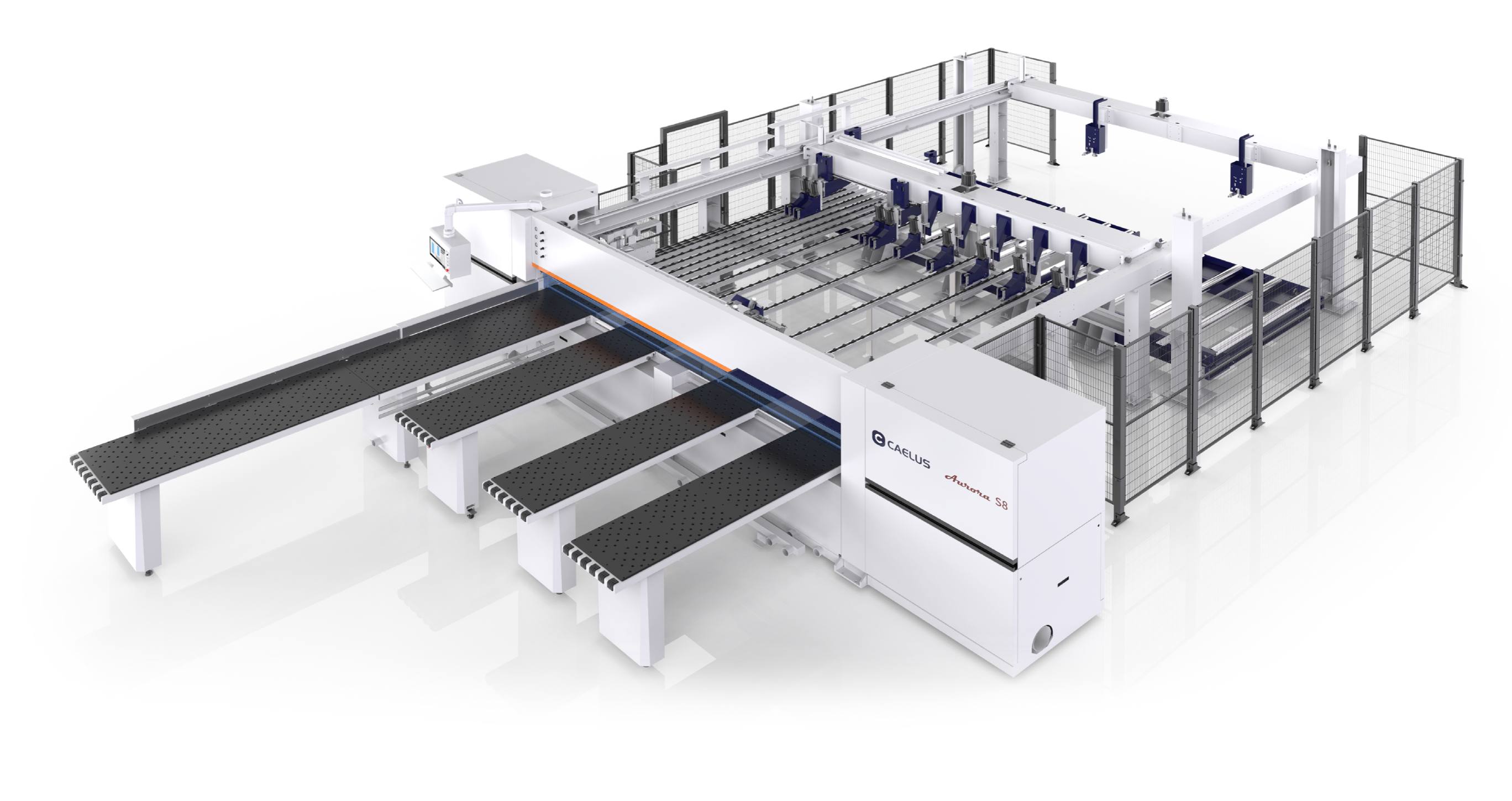

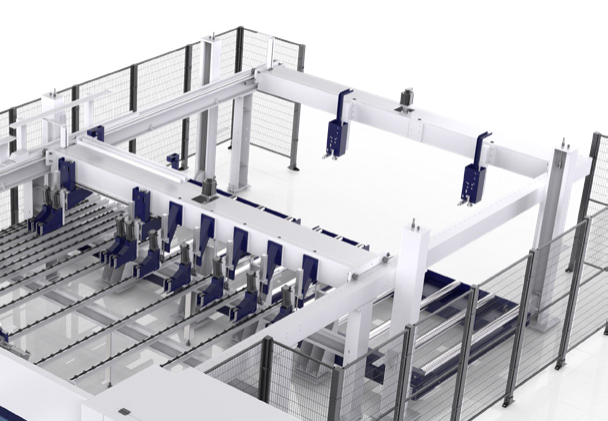

Rear loading and double stacking auxiliary system, dual crossbeam structure.

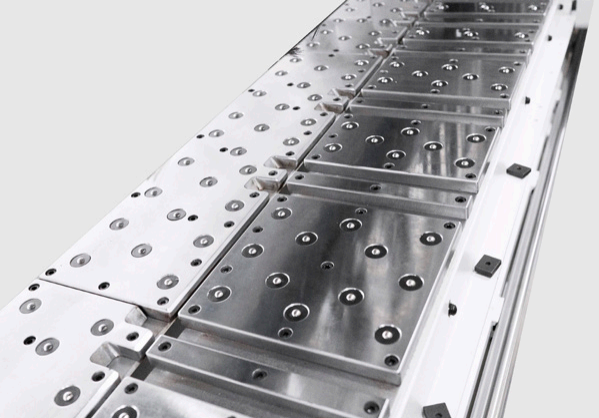

Fully air-cushioned steel table moves parts more smoothly to protect sensitive surface without damage.

Core highlights:

1. The saw carriage drive system adopts servo control and a high-rigidity, high-precision and high-dustproof linear guide structure, which can automatically position the sawing stroke according to different sawing widths, reduce idle stroke time, and improve work efficiency. The maximum sawing speed can reach 160m/min.2. The main saw uses a 22KW (variable frequency) permanent magnet synchronous motor with high torque, low noise, wide speed adjustment range, fast response, and green energy saving. When not sawing, the speed automatically decreases, which can adapt to large-scale rapid cutting. The maximum return speed can reach 200m/min.

3. The main saw and the auxiliary saw adopt independent lifting control systems. The main saw lifting adopts servo control and electric cylinder transmission structure, which can automatically adjust the lifting height according to the sawing thickness to achieve the best sawing effect.

4. Equipped with 2 The servo-controlled moving mechanical clamp breaks the conventional rules and adjusts the optimal clamping position according to the different plate sizes to ensure the cutting effect.

5. Equipped with a servo double pusher device, which consists of two sets of main and auxiliary manipulators. The two sets of pushers are independently driven and work together to saw two plates of different sizes at the same time, which can improve the efficiency by 30%.

6. Double beam feeding system: the clamp and pusher operate independently, and processing and loading are carried out simultaneously, reducing the waiting time for loading and improving the loading efficiency by 20%.

7. The pressure beam lifting adopts a high-precision double-tie rod cylinder with special pneumatic control to achieve automatic lifting and positioning. The lifting distance can be adjusted according to the thickness of the plate, reducing the cylinder's idle stroke and improving the sawing efficiency.

8. The work surface adopts an air-floating bead steel surface, which makes the plate movement easier, ensuring the processing of sensitive decorative panels and preventing the plate from being scratched.